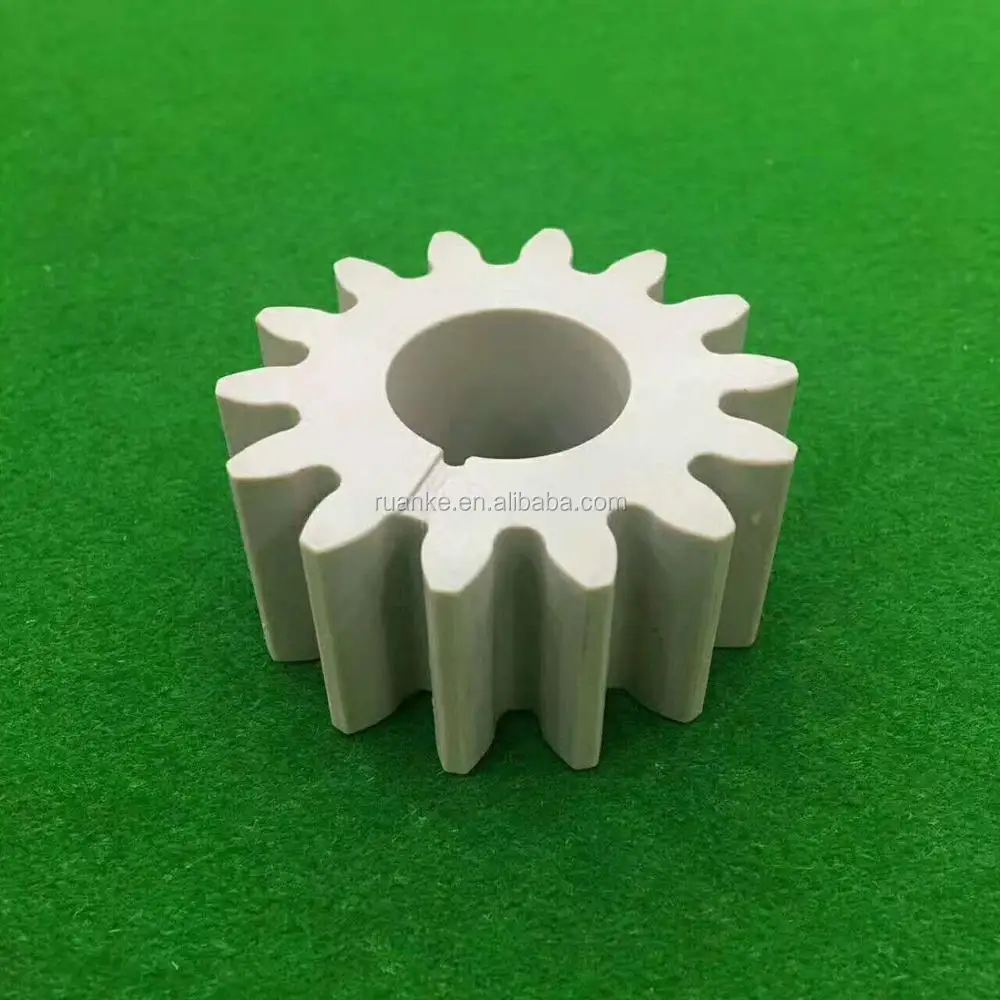

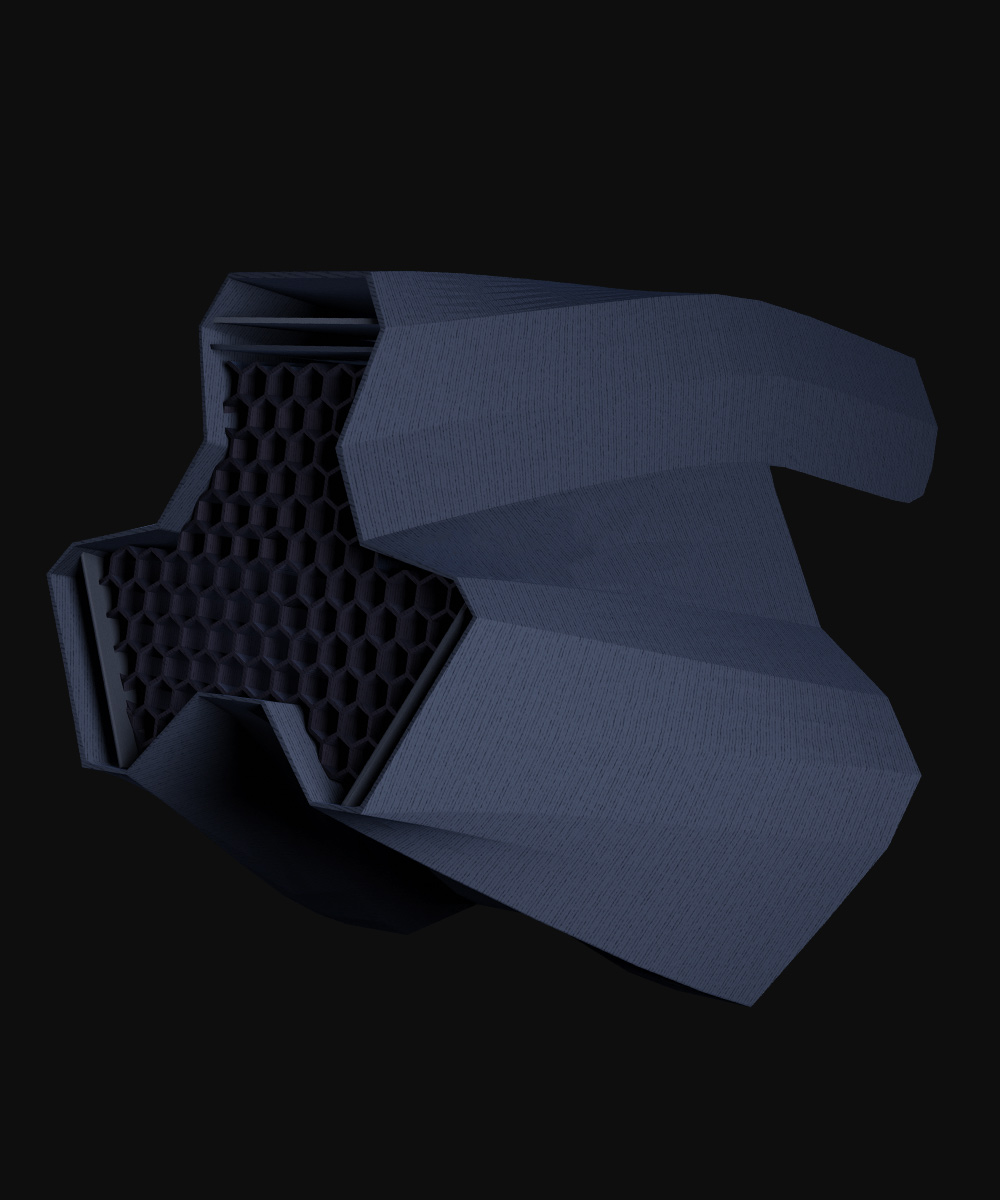

It is highly resistant to thermal degradation, as well as to chemicals or water.***īecause of these PEEK material properties, it is an excellent choice for applications from aerospace to biomedical. Some grades have a useful operating temperature of up to 250 ☌ (482 ☏). PEEK has a glass transition temperature of around 143 ☌ (289 ☏) and melts around 343 ☌ (662 ☏). It is also radiolucent, meaning it is almost entirely invisible in x-ray photographs and under fluoroscopy. PEEK material has excellent strength, hardness, and temperature resistance.

PEEK has been used as a spinal implant since the 1980s, with efficacy and safety. Its resistance to chemicals and strength at high temperatures make it ideal for these applications. PEEK material can be used in the production of seals and brake components for vehicles. PEEK is also lighter than metals, leading to fuel efficiencies. AerospaceĪircraft parts made of PEEK are chemically resistant to jet fuel, de-icing solutions, steam, salt, water, and hydraulic fluid.

This innovative thermoplastic offers temperature, chemical, and abrasion resistance. Peek material properties make it suitable for many different applications. PEEK material has the ability to maintain stiffness at high temperatures, giving it a proven track record in challenging environments such as aerospace, automotive, and electronics. PEEK (polyetheretherketone) is a high-performance organic thermoplastic polymer with excellent mechanical strength.

0 kommentar(er)

0 kommentar(er)